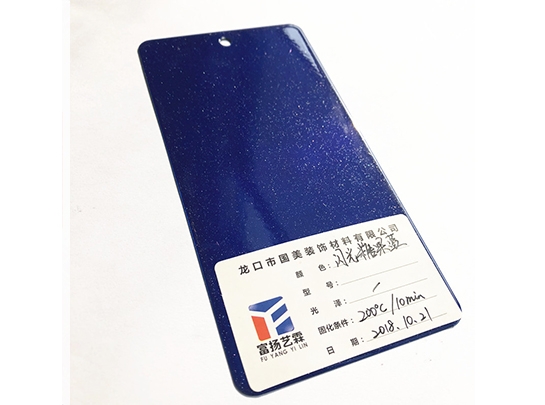

The main raw materials of spray powder manufacturers are acrylic powder, polyester powder, etc. Spray plastic is often said to be electrostatic powder spraying, it is the use of electrostatic generator to make plastic powder charged, adsorbed on the surface of iron plate, then after 180 ~ 220 ℃ baking, so that the powder melts adheres to the metal surface. Plastic spraying products are mostly used for indoor use of the box, the paint film presents a smooth matte effect. Plastic spraying is a surface treatment method of spraying plastic powder on parts. Spray painting is also known as electrostatic powder spray coating. Its treatment process is a kind of metal surface treatment decoration technology widely used in the world since 1980s. Compared with the common spray painting surface treatment, the advantages of this technology are advanced technology, energy saving high efficiency, safety reliability, bright color so on. Therefore, it is often used in the field of light industry home decoration. Its working principle is that the plastic powder is charged by high-voltage electrostatic equipment, the coating is sprayed on the surface of the workpiece under the action of electric field, the powder will be evenly adsorbed on the surface of the workpiece to form a powder coating; while the powder coating is flat solidified after high temperature baking, the plastic particles will melt into a layer of dense final protective coating with different effects, firmly adhere to the surface of the workpiece noodles.

The phone:13396380707

86-535-8927111

fax:86-535-8927112

The url:shop1409675938801.1688.com

email:lkfyyl0930@163.com / lkbestsun@163.com

address:Wenhua Road, Beima Town, Longkou City, Shandong Province, China

Focus on WeChat

Mobile station